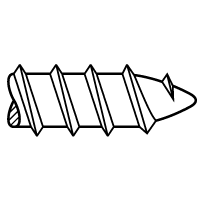

Sheet Metal Type A

For self starting in thin

(.015 to .050 thick) metal or

resin-filled plywood.

|

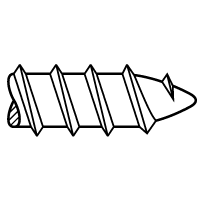

Sheet Metal Type AB

Designed for use in the thinner

sheet metal commonly used today,

particularly in appliances.

|

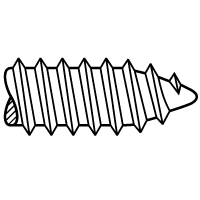

Sheet Metal Type B

For molded or through holes

in thin metal, non-ferrous castings.

|

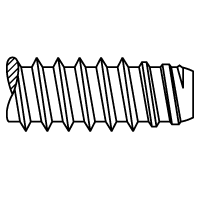

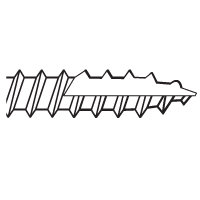

High-Low

For use in plastic, nylon, and wood.

Thread design reduces driving torques,

enhances resistance to thread stripping,

and improves pullout strength.

|

Self-Piercing

To be used in thin metal

(less than .050 thick). Eliminates

need for pre-drilled holes. Undercut area

beneath the head allows greater length of

thread engagement. Twin lead threads

reduce driving torque.

|

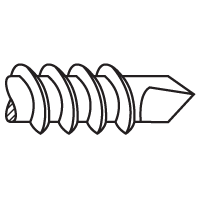

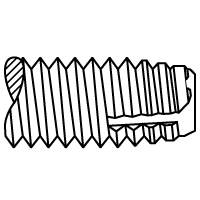

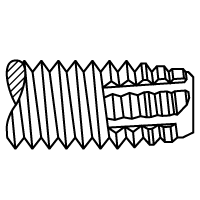

Self Drilling Type BSD

This screw drills its own hole in metal.

Can attach metal to metal; or composition

board, plywood or soft woods to metal.

|

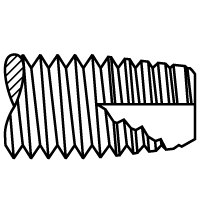

Self Drilling Type CSD

Also drills its own hole; usually

preferred over Type-BSD drill screws

when fastening thicker materials.

|

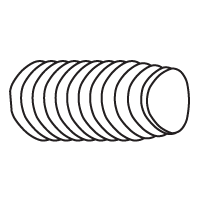

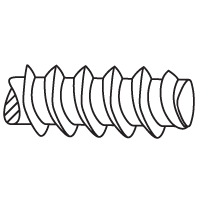

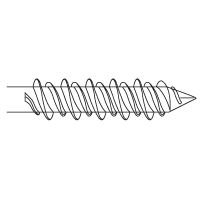

Thread Rolling Taptite®

For drilled, punched or cored holes in

all ductile metals and punch extruded metals.

Eliminates chips, requires low drive torque and

is resistant to vibrational loosening.

|

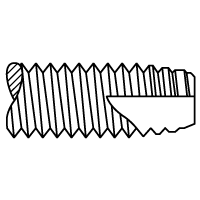

Thread Rolling Plastite®

Used in thermoplastics, engineering resins

and certain thermosets. The 48° thread

profile increases holding strength while

reducing material displacement.

|

Thread Cutting Type 1

Steel: Used in steel sheets, structural

shapes, special alloy steels, cast iron,

brass or plastics. Stainless: Material into

which the screw is to cut threads should

have a lower hardness by 10-20 Rockwell

hardness points.

|

Thread Cutting Type 23

Provides excellent chip clearance with

minimum tightening torques. Steel: Used in

cast iron and zinc, aluminum die castings,

and plastics. Stainless: Material into which the screw

is to cut threads should have a lower hardness by

10-20 Rockwell hardness points.

|

Thread Cutting Type 25

Provides excellent chip clearance.

Steel: Used in molded or through

holes in plastics and other soft materials.

Stainless: Material into which the screw

is to cut threads should have a lower

hardness by 10-20 Rockwell hardness points.

|

Thread Cutting Type F

Steel: Used in heavy gauge sheet

metal, aluminum, zinc and lead

die castings, cast iron, brass and plastic.

Stainless: Material into which the screw is to

cut threads should have a lower hardness by

10-20 Rockwell hardness points.

|

Type 17

Used in decking materials including

woods with medium density and

composite materials.

|

Masonry | Concrete Screw

Cuts its own threads when used

in concrete, block or brick. Carbide

bits are recommended for use in masonry.

|

Drive Screw Type U

For making permanent fastenings i

n metals and plastics, when forced

into the work piece using pressure.

|

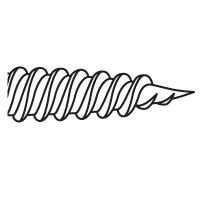

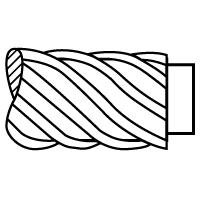

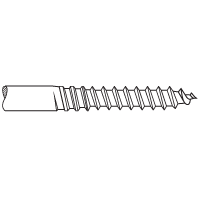

Wood Screw | Full Body

Will produce a mating thread

when assembled into wood or

other resilient materials.

|

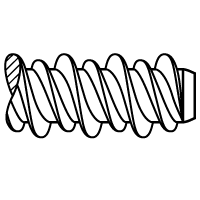

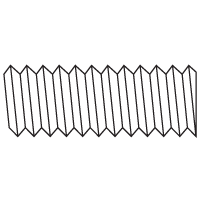

Machine Screw | Cap Screw

Designed to go through a hole

or nut that is pre-tapped to form

a mating thread for that screw.

|